Product Description

InkAID Clear Gloss Type II Inkjet receptive coating can be applied to any material that goes through your inkjet printer. It provides a clear gloss finish that allows the underlying surface to appear through the coating.

It is the recommended coating for use on metals (unlike the other inkAID coatings that lean towards porous substrates), film, and other non-porous materials, as it contains an additive that provides firm adhesion to these surfaces and improves over time.

You can use it on paper and other porous materials. One coat usually provides sufficient coverage, but porous materials such as paper may need a second coat. It is not water resistant. So, to improve your prints' water resistance, scratch resistance, and lightfastness with inkAID Clear Gloss Type II, you should apply a solvent-based or epoxy top coating after printing.

Instructions for using the Clear Gloss Type II

All inkAID coatings work best at 21-27 degrees C, from initial stirring to application. Read and follow the directions on the label.

Always stir the coating gently but thoroughly from the bottom using a clean spatula or spoon before use.

inkAID Clear Gloss Type II coating cleans up with water, even after drying. Wear appropriate clothing and work in an area suitable for painting.

Never work directly from the container. Always pour a working amount of inkAID Clear Gloss Type II coating into another clean container. Never pour unused coating back into the container.

Ensure all your tools and brushes are clean and dry before beginning work. Store inkAID Clear Gloss coating in a cool, dry environment above 12 degrees C. Never allow the coating to freeze.

The final appearance of your print will depend on how much coating is on the surface of the substrate. Be sure to coat the entire surface of the substrate thoroughly. The inkjet receptive coating absorbs most of the ink and adequately positions the ink droplets to create the print.

Porous substrates like paper, fabric, and canvas will absorb some of the coating into the material, but enough is left on the surface to provide excellent printability. Usually, less coating can be used on porous substrates as it will absorb a significant amount of the ink vehicle. When getting started with a new substrate, test a few small pieces. Non-porous substrates like metal, plastic, and film will have all the coating on the surface. The coating must absorb all of the ink with these substrates, so a heavier coating layer is needed. Make sure your substrate is on a smooth, level surface.

All metals must be cleaned thoroughly to remove processing oils before coating with inkAID Clear Gloss Type II. Always check your printer specifications to determine the maximum media thickness for your printer.

inkAID coatings will impart a slightly stiffer hand to lighter-weight papers and fabrics.

Applying inkAID Clear Gloss Type II Coating

Always work with clean tools and brushes. inkAID Clear Gloss Type II coating can be applied with a foam brush, good quality bristle brush, coating rod, or a Paasche VLS Airbrush sprayer.

When applying with a brush, a good practice is to work in one direction and then again at a 90-degree angle to ensure complete coverage.

inkAID Clear Gloss Type II is self-levelling, so the inkjet receptive coating layer can't include brush strokes. The post-print top coating step can add brush strokes and other embellishments.

When using a brush to coat metal or another non-porous substrate, pour enough coating into the centre and gently push the coating to cover the entire surface. You want a heavier coating layer, so if some fall off the edges, that's fine. A coating rod is a straightforward and precise way to apply the coating.

Porous substrates like paper will absorb water and swell. This can cause slight curling upon drying.

You can tape the substrate down to a working surface using de-tackified blue painter's tape. Coat the sheet and let it dry in place. De-tackify the tape by sticking it to a cloth and pulling it off. This will add some fibres to the tape and reduce the adhesion. This will help protect the surface of your substrate when the tape is removed. Another way is to hang the wet-coated substrate from a thin wire (using metal clips or clothespins to hold it in place), allowing gravity to pull it down and remain flat as it dries. Additional metal clips can be placed on the bottom of the hanging substrate to add extra weight.

If the substrate is still curled after drying, it can be pressed flat using several methods. One is to place it between two flat pieces of material, such as Plexiglas, and load a heavy weight overnight or for a few days. Another way would be to put sheets of parchment paper above and below the coated sheets and use a heat press or warm iron. Sheets can also be flattened by holding the top and bottom and running them over the edge of a table or countertop. Allow the coating to dry completely before printing. inkAID Clear Gloss Type II coating usually dries in several hours depending on the amount applied, ambient temperature, and humidity press.Larger sheets can be reversed and rolled (coated side out) onto a 4- or 6-inch-diameter cardboard tube to remove the curl.

A Few Tips About Printing

You may have to attach them to a carrying sheet to print on very lightweight papers or fabrics. A carrying sheet supports and stabilizes the coated substrate so you'll print precisely where you want to on the sheet.

The printer settings should be initially set to "gloss" media. But, because you are working with a custom substrate, you should test several different media settings to find the best one.

Post Print Coatings (Top Coatings)

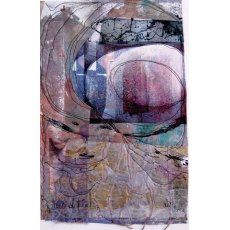

Top coatings, applied after printing, provide the final finish to your print. They also offer scratch, water, UV and ozone resistance, which maintains your fine art print's colour (lightfastness).

A solvent-based top coating must be used over inkAID Clear Gloss Type II because it is not water resistant. Recommended top coatings include Art Resin (especially over metal prints), Golden MSA Varnish, and Premier Art solvent-based top coatings.

Customer Reviews

In stock

In stock